WIDTH GAUGES.

Gauges for single strip or multistrips.

Measuring heads with high-level protection for optoelectronic components.

LED technology solutions with backlight system or LASER technology without backlight.

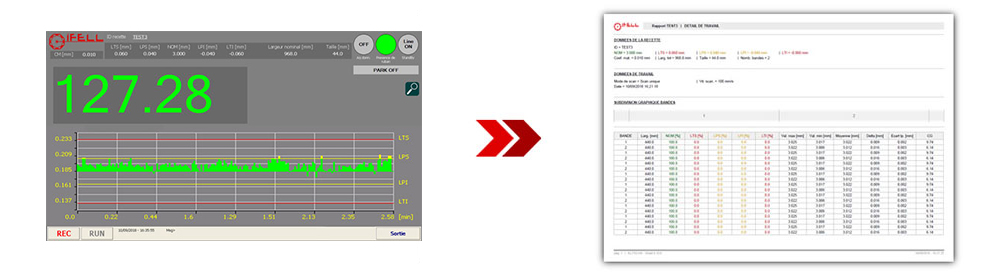

Intuitive operator panel for real time display of measurements in graphic and digital form.

Automatic data report shared on local network.

Data and signals exchange on field bus for automatic processing lines.

TYPICAL APPLICATIONS

Slitting lines

Cut to length lines

Galvanizing / pickling / finishing lines

Foam extrusion lines

HLW SINGLE STRIP width gauges

For continuous measurements of strips directly on production line.

Gauges can be installed in fixed position or moveable from parking to measuring point by means of linear translation stages.

The out of line parking position allows to safely insert the material before gauge insertion at the measuring point.

HLW-scan MULTISTRIP width gauges

To measure parallel and well-separated strips after longitudinal cut, directly on production line.

The strips are quickly and safely measured in sequence one after the other immediately at the entrance of each coil.

Gauges can measure up to 80 strips in a scanning width up to 2200 mm.

Width measurement can also be combined with thickness measurement in the same gauge to achieve a double function in a single machine.

HOW IT WORKS

HLW gauges are designed to measure the width of flat materials with the telecentric optical projection principle.

Material is illuminated from the backside by homogeneous light source. At the opposite side, a photodetector reads the light/dark transition produced by the material edge.

Since the optical system generates a parallel light projection, the measure is stable even if the material has a certain displacement from the nominal pass-line.

VLW SINGLE STRIP width gauges

For continuous measurements of strips of any width without backlight under the material.

One or two measuring heads are used to cover the material width range. In some cases the size of the measuring range can be wide enough to cover the whole material with fixed installation, without the need to reposition the heads at material change.

HOW IT WORKS

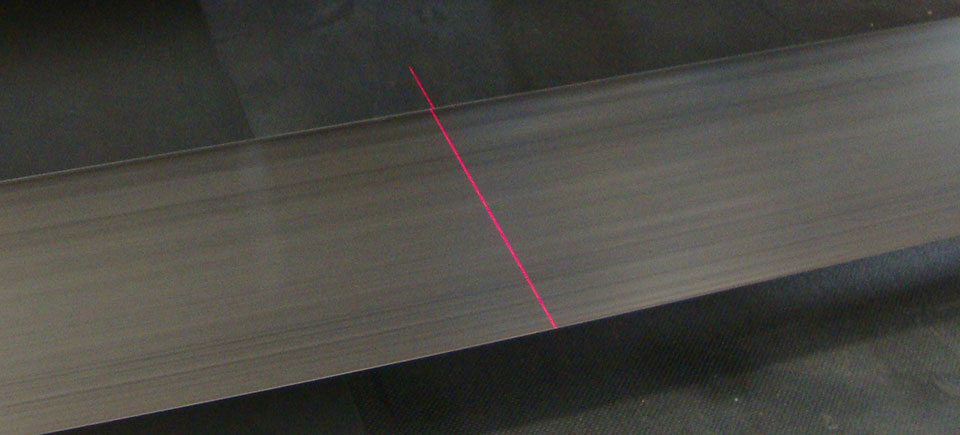

VLW are based on the laser line triangulation principle. A narrow laser line is projected on the material edge area from a certain working distance.

The width of the material, running in a specified measuring range, is calculated by means of an accurate optical system placed at a certain angle.